About Us

About Us

Poona Sarees and Dress Materials a popular brand in Pune can be equated to the famous ‘Shaniwar Wada’. Courtesy to the oldest surviving names in this trade, started by Kunden Family.

The company was started way back in Pune in 1930 by late Shri Narsayya Sayyana Kunden, the father of Mr.Subhash Kunden. In the beginning, he himself went from door to door to sell the sarees which he had woven himself and created a small customer base then. In the year 1965 it was the brainchild of Mr. Subhash Kunden for branding this product as ‘Poona Sarees’ which went on to become an household name till date in Pune.

Timeline

The company was started way back in Pune in 1930 by late Shri Narsayya Sayyana Kunden, the father of Mr.Subhash Kunden. In the beginning, he himself went from door to door to sell the sarees which he had woven himself and created a small customer base then.

In the year 1965 it was the brainchild of Mr. Subhash Kunden for branding this product as ‘Poona Sarees’ which went on to become an household name till date in Pune.

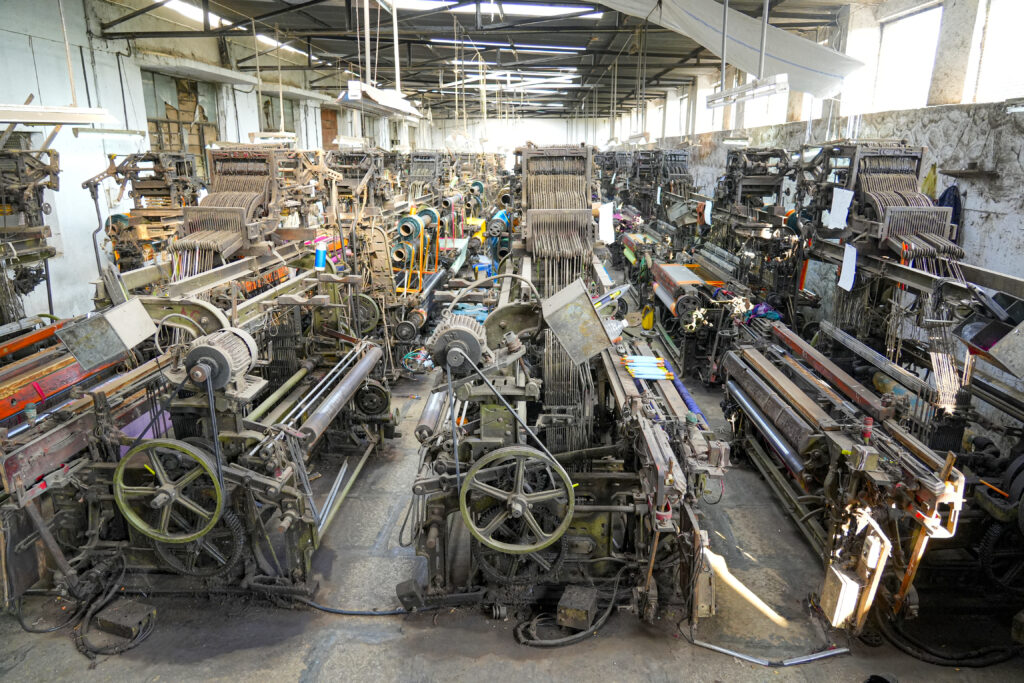

Till 1970, there were 3000 looms in Poona. All operated by the Padmashali Telugu Community, out of which only few survived and the chosen one amongst them were Kunden family, the credit for the same should go to Mr. Subhash Kunden, who with his vision and commitment towards rapid changes and transition within the product as per the market requirement, helped in sustaining till date.

After the split from joint family, in 2001 Mr. Subhash Kunden has started a Factory in the name of “SHREE CHINTAMANI SILK MILLS PVT LTD” situated at Theur Village, Pune (home of one of the Holy Ashtavinyakas), along with a Marketing Division in the name of S.N. Kunden with an installation capacity of around 100 power looms with streamline process catering to greater quality of the product along with higher efficiency and production so as to sustain the Demand Supply Ratio

As a product extension, the company started manufacturing Dress Materials, more so in keeping with the trend and the products with superior quality became instant hit and the manufacturing of Dress Materials increased manifolds. These Dress Materials are exclusively made from superior cotton and can be used to stitch Designer Wear Salwaar-Kameez, Western Outfits, Kurtas and much more.

Our Capabilities

- Transition

- Marketing

- Production

- Quality

Over the years, we have been providing our patrons the best quality “Poona Sarees and Dress Materials” with contemporary borders & timely changes in styles and combinations relevant to market requirement. Keeping the 21st century women in mind, the 3rd generation of the family Mr Anil S. Kunden and Mr Sunil S. Kunden made some transition into the product by developing new variants and styles in terms of value addition such as prints, embroideries, new combinations, silk based fabrics etc,

Marketing is the backbone of any company. In view with the Goodwill of the Kunden in the market, all the products are marketed through Proprietor firm S.N. Kunden. We believe in Customer Satisfaction and value for their money. Hence of 8 to 10 Sales Representatives plying all over India for fetching and catering the orders. We have strong demand from all the parts of India such as Mumbai, Bangalore, Delhi, Kolkata, Ahmedabad, Chennai, Hyderabad and above all Pune.

Quality being one of the major aspect of any product, we follow stringent norms and thorough flow of process in manufacturing our product. Our product comprises of following aspects to assure credibility of the fabric.

- Use of best cotton yarns and its blends.

- Use of eco-friendly dyes.

- Providing good texture, Comfort and Durability

- Woven using quality machines

- Good Color Fastness.

- Providing luxurious sheen to the Fabric due to Teflon Finishing Treatment (helps in enhancing dimensional stability of the material).

- Less maintenance Fabric